plastic guide

Plastics are versatile materials used extensively in modern life, offering durability and cost-effectiveness across industries. Their adaptability makes them essential for applications ranging from packaging to healthcare.

1.1. What Are Plastics?

Plastics are synthetic or semi-synthetic materials made from polymers, which are long chains of repeating molecules. They are lightweight, durable, and can be molded into various shapes and forms; Common types include thermoplastics and thermosets, each with unique properties. Plastics like PET, PVC, and polyethylene are widely used due to their versatility and cost-effectiveness. Their ability to be shaped and formulated for specific purposes makes them indispensable in modern manufacturing and daily life.

1.2. Importance of Plastics in Modern Life

Plastics play a vital role in modern society, offering unparalleled versatility and convenience. They are integral to industries like healthcare, packaging, and transportation, enabling the creation of lightweight, durable, and cost-effective products. Plastics enhance safety, improve efficiency, and contribute to technological advancements. Their adaptability ensures they meet diverse needs, from medical devices to everyday household items, making them indispensable in driving innovation and improving quality of life globally.

History and Evolution of Plastics

Plastics originated in the mid-19th century with Parkesine, evolving through innovations like Bakelite. Their development revolutionized industries, shaping modern society with versatile, durable materials.

2.1. Early Development of Plastics

The early development of plastics began in the mid-19th century with Parkesine, a material derived from cellulose. Invented by Alexander Parkes in 1855, it was showcased at the Great Exhibition in London. Later, Bakelite, the first fully synthetic plastic, was developed by Leo Baekeland in 1907, marking a significant milestone. These innovations laid the foundation for modern plastics, overcoming challenges like cost, durability, and material availability, paving the way for their widespread use.

2.2. Key Milestones in Plastic Production

Plastic production advanced significantly with the invention of Polyvinyl Chloride (PVC) in the 1930s, offering flexibility and resistance to chemicals. The 1940s saw the rise of Teflon, revolutionizing non-stick surfaces. In the 1950s, polyethylene became widely used in packaging, while polypropylene emerged in the 1950s, known for its strength and versatility. The 1970s introduced polyester, enhancing textiles and packaging. Each milestone expanded plastic applications, driving innovation and industrial growth globally.

Types of Plastics

Plastics are categorized into thermoplastics, thermosets, and specialized plastics. Thermoplastics, like polyethylene, can be melted and remolded, while thermosets, such as epoxy, harden permanently when cured. Specialized plastics include biodegradable and high-performance polymers tailored for specific uses, ensuring versatility across various industries and applications.

3.1. Thermoplastics

Thermoplastics are plastics that can be melted and remolded repeatedly without undergoing chemical change. Common examples include polyethylene, polypropylene, and PVC. These plastics are known for their flexibility, durability, and ability to be recycled. They are widely used in packaging, consumer goods, and automotive parts due to their adaptability and cost-effectiveness. Thermoplastics can be molded into various shapes and are often used in applications requiring high impact resistance and thermal stability, making them a cornerstone of modern manufacturing and design.

3.2. Thermosets

Thermosets are plastics that cure into a permanent shape after being molded, unable to be remelted. Once set, they exhibit high thermal stability, chemical resistance, and durability. Common examples include epoxy, polyester, and polyurethane. Thermosets are widely used in adhesives, electrical components, and high-temperature applications. Their rigidity and strength make them ideal for structural uses, though they cannot be recycled like thermoplastics. This makes them a critical material for industries requiring long-lasting, heat-resistant solutions.

3.3. Additives and Specialized Plastics

Additives enhance plastics’ properties, such as flexibility, heat resistance, or color. Examples include plasticizers, flame retardants, and UV stabilizers. Specialized plastics, like polycarbonate and polyethylene, are engineered for specific uses. These materials are crucial in industries requiring high performance, such as electronics, healthcare, and aerospace. Additives and specialized plastics enable tailored solutions, addressing diverse challenges and improving product functionality across various applications.

Environmental Impact of Plastics

Plastic pollution harms ecosystems, contaminating oceans and soil. Its persistence in the environment raises concerns about long-term ecological and health impacts, necessitating sustainable solutions.

4.1. Plastic Pollution and Its Effects

Plastic pollution has become a critical global issue, with millions of tons of waste entering oceans and landfills annually. Improper disposal leads to environmental degradation, harming marine life and ecosystems. Plastics break down into microplastics, which infiltrate the food chain, posing risks to human health. The persistence of plastics in the environment, taking centuries to decompose, exacerbates long-term ecological damage. Addressing this requires urgent action, including reduced plastic use, improved waste management, and innovative recycling solutions to mitigate these harmful effects.

4.2. Biodegradable Plastics

Biodegradable plastics are designed to break down naturally through microbial action, reducing environmental persistence. Made from renewable resources like corn starch or sugarcane, these plastics decompose faster than traditional plastics. They offer a more sustainable alternative, minimizing pollution in oceans and landfills. However, their effectiveness depends on proper disposal, as they require specific conditions to degrade fully. While biodegradable plastics are a step toward sustainability, they are not a complete solution to plastic pollution, but they contribute to reducing its long-term impact.

Health Considerations

Plastics are widely used in food packaging and healthcare, ensuring safety and hygiene. However, certain chemicals like BPA and phthalates raise health concerns, prompting regulatory scrutiny.

5.1. Safety of Plastics in Everyday Products

Plastics in everyday products are generally safe when manufactured to meet regulatory standards. However, concerns arise with certain chemicals like BPA and phthalates, linked to potential health risks. Proper testing and certification ensure products like food packaging and toys are safe for use. Regulatory bodies enforce guidelines to minimize exposure to harmful additives. Despite these measures, ongoing research and public awareness are crucial to address lingering safety concerns and promote safer alternatives. Balancing innovation with health protection remains a priority in plastic production.

5.2. Chemicals in Plastics and Human Health

Certain chemicals in plastics, such as BPA and phthalates, have raised health concerns due to their potential to disrupt endocrine systems. These substances can leach into food or environments, posing risks to human health. Regulatory bodies have imposed restrictions on their use in products like baby bottles and food packaging. While many plastics are safe, ongoing research and stricter regulations aim to mitigate risks and promote the development of safer, non-toxic alternatives for consumer products.

Recycling and Sustainability

Plastic recycling transforms used materials into new products, reducing waste and conserving resources. Sustainable practices aim to minimize environmental impact through efficient waste management and eco-friendly innovations.

6.1. How Plastic Recycling Works

Plastic recycling involves collecting, sorting, and processing used plastics into raw materials for new products. The process starts with gathering waste plastics, which are then sorted by type and cleaned. Advanced technologies like mechanical recycling break down plastics into smaller particles, while chemical recycling converts them into original monomers. These materials are then reused to manufacture fresh products, reducing the need for virgin plastics and promoting sustainability. Efficient recycling relies on proper waste management and public participation to maximize environmental benefits.

6.2. Innovations in Plastic Waste Management

Recent advancements in plastic waste management include advanced recycling technologies and biodegradable plastics. Innovations like chemical recycling break down plastics into monomers, enabling the creation of high-quality new products. Additionally, researchers are developing enzymes that can degrade plastics faster, reducing environmental impact. Waste-to-energy technologies are also emerging, converting non-recyclable plastics into clean energy. These innovations aim to minimize plastic waste while promoting a circular economy, ensuring plastics are reused rather than discarded;

Applications of Plastics

Plastics are widely used in packaging, healthcare, automotive, aerospace, electronics, and consumer goods due to their durability, versatility, and cost-effectiveness, making them indispensable across industries.

7.1. Plastics in Packaging

Plastics are essential in packaging due to their versatility, durability, and cost-effectiveness. They are used in bottles, containers, wraps, and films, ensuring products remain fresh and protected. Lightweight plastics reduce transportation costs and carbon emissions. Common types include PET for bottles and HDPE for containers. Plastics also prevent spoilage and extend shelf life, making them indispensable in food and beverage industries. However, their environmental impact has led to innovations like biodegradable plastics, aiming to balance functionality with sustainability.

7.2. Plastics in Healthcare

Plastics play a vital role in healthcare, enabling the creation of medical devices, packaging, and disposable items. Their sterility, flexibility, and durability make them ideal for surgical instruments, gloves, and implants. Lightweight plastics reduce transportation costs and enhance portability of medical equipment. Innovations like biocompatible plastics are improving patient safety, while recycling initiatives aim to address environmental concerns. Plastics’ versatility ensures they remain critical in advancing healthcare, balancing performance with sustainability and patient well-being.

7.3. Plastics in Automotive and Aerospace

Plastics are integral to automotive and aerospace industries, enhancing performance and safety. Lightweight plastics reduce vehicle weight, improving fuel efficiency and lowering emissions. In aerospace, they enable durable, high-performance components. Plastics are used in dashboards, seating, and exterior parts in cars, while in aircraft, they form lightweight yet strong structures. Thermoplastics and thermosets are key materials, offering flexibility and resistance. Recycling efforts focus on reusing automotive plastics, while innovations like carbon fiber-reinforced polymers advance aerospace applications, ensuring plastics remain vital for future transportation needs.

Regulations and Standards

Regulations and standards govern plastic use to ensure safety and reduce environmental impact. Global certifications promote sustainable practices, while industry-specific standards ensure product quality and compliance.

8.1. Global Regulations on Plastic Use

Global regulations on plastic use aim to reduce environmental and health impacts. Many countries have implemented bans on single-use plastics, while others enforce strict recycling standards. The European Union has introduced measures to limit plastic waste, and the United Nations promotes global agreements to address plastic pollution. These regulations often include restrictions on harmful additives and require manufacturers to adopt sustainable practices. Compliance with these standards is crucial for ensuring safer products and minimizing ecological harm.

8.2. Certifications for Safe Plastic Products

Certifications ensure plastic products meet safety and quality standards. Programs like BPA-free and FDA compliance verify safety for food contact. The EU’s REACH regulation restricts harmful chemicals, while Cradle to Cradle certifies sustainable materials. These certifications guide consumers and manufacturers in choosing safer, eco-friendly options, promoting trust and environmental stewardship across industries.

Future of Plastics

The future of plastics lies in sustainable practices, innovative materials, and a circular economy, driving eco-friendly solutions and reducing environmental impact significantly for a better tomorrow.

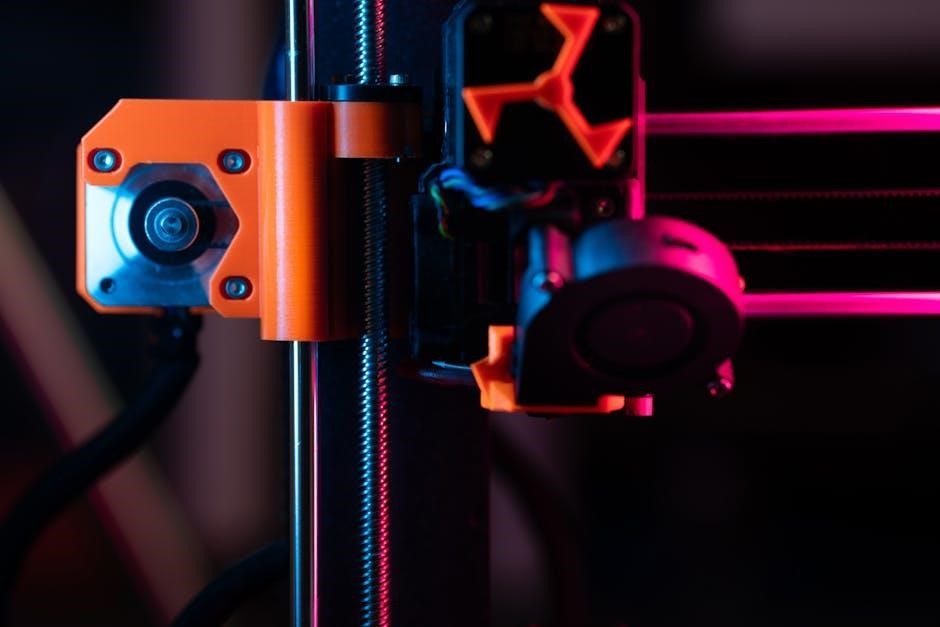

9.1. Emerging Technologies in Plastic Production

Emerging technologies in plastic production focus on sustainability and efficiency. Biodegradable plastics, nanotechnology, and advanced recycling methods are revolutionizing the industry. Innovations like chemical recycling and 3D printing enable precise material creation, reducing waste. AI and machine learning optimize production processes, improving material properties and reducing environmental impact. These advancements aim to create eco-friendly plastics while maintaining performance, paving the way for a sustainable future in manufacturing and material science.

9.2. Circular Economy and Plastics

The circular economy aims to transform plastic production into a sustainable, closed-loop system. It emphasizes recycling, reusing, and designing products for longevity. By adopting circular practices, the plastic industry can reduce waste and environmental impact. Strategies include developing recyclable materials, improving recycling technologies, and promoting biodegradable plastics. This approach aligns with global sustainability goals, encouraging innovation and collaboration across industries. A circular economy ensures plastics remain valuable resources, minimizing their harmful effects on the planet and fostering a greener future.

Plastics revolutionized modern life with their versatility, but their environmental impact demands careful management. Balancing innovation and sustainability is key to ensuring plastics benefit society responsibly.

10.1. The Role of Plastics in Society

Plastics play a vital role in modern society, offering versatility and durability across industries. From healthcare to packaging, they enhance convenience and safety. Their lightweight and cost-effective nature makes them indispensable. However, their widespread use raises environmental concerns. Striking a balance between innovation and sustainability is essential to ensure plastics continue benefiting society responsibly, fostering both progress and ecological preservation. Their impact underscores the need for mindful consumption and advanced waste management strategies.

10.2. Balancing Convenience and Sustainability

Balancing convenience and sustainability is crucial as plastics remain integral to modern life. While they offer versatility and cost-effectiveness, their environmental impact necessitates responsible use. Recycling, biodegradable alternatives, and innovative waste management can mitigate harm. Encouraging sustainable practices without sacrificing convenience requires collaboration between industries and consumers. By prioritizing eco-friendly solutions, society can enjoy the benefits of plastics while minimizing their ecological footprint, ensuring a future where convenience and sustainability coexist harmoniously.